Metallic Epoxy Resin Floor Coating

Metallic Epoxy Resin Floor Coating

Metallic Epoxy Supplemental Instructions

MTBJZJ Metallic Epoxy System. In addition to our standard floor coating instructions, please see below for additional information to help you achieve excellent results. Be sure to follow both sets of instructions.

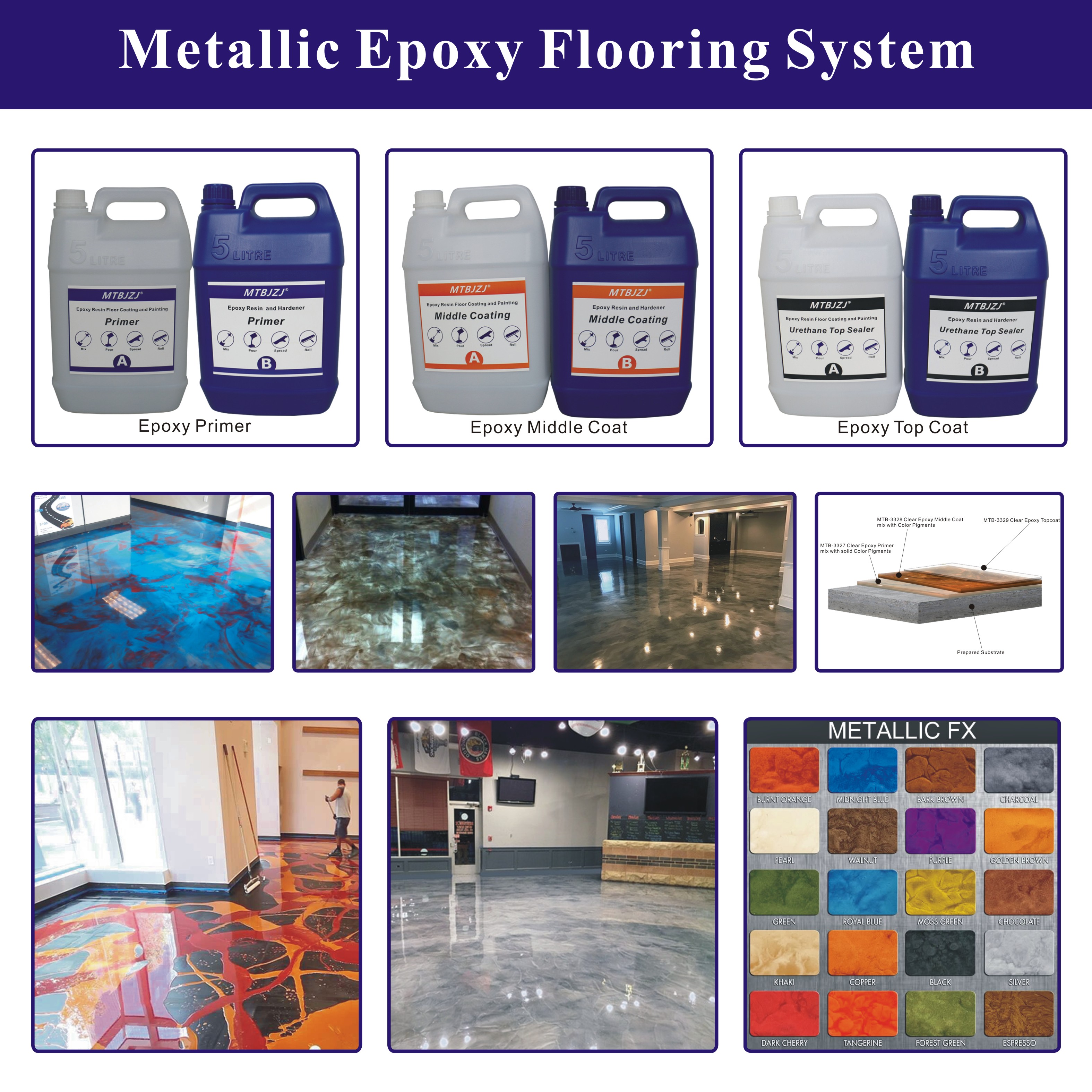

Metallic epoxy is a three layer system that uses a colored based epoxy primer.Once cured, then a coat of 100% solids clear epoxy with metallic powder additive gets applied in a decorative fashion to get the ‘look’. Once this is cured, then a clear protective topcoat is applied. Use of spiked shoes to walk on the wet epoxy is strongly suggested. Please note that metallic epoxy is a somewhat artistic method of application, so check online videos for some helpful tips and suggestions as to technique. Note that in addition to technique, temperature, application timing, speed of application, color choices, primer color selection, and humidity can all greatly affect final outcome appearance and it is almost impossible to replicate results from project to project due to these variables.

Note For The Reason That There Are So Many Variables To Metallic Epoxy Application, And The Process Is Very Technique-dependent, Armorgarage Cannot Guarantee Results, ‘look’, Appearance, Matching To Photos, Or The Outcome Of A Metallic Epoxy Installation. Such Things As Uneven Finish, Roller Marks, And Other Results Which The User May Not Be Pleased With Cannot Be Guaranteed By Armorgarge And Are Not Covered By Our Warranty.

1.Apply colored primer (usually black or gray) to the floor. Mix per label instructions. Let cure overnight.

2. Add the proper quantity of metallic powder to all of your Part A’s accordingly. Mix in thoroughly. This step gives you an even Part A to work with.

If You Plan On Using Two Colors Of Metallic, Evenly Divide

Your Part A And Mix Your Color Powders Evenly Into Each Part A So You Have On Hand The Pre-colored Part A Which You Will Later On Mix With The Part B.

3. do not mix with part b yet.

4. Plan the metallic application step by figuring how much epoxy you can mix, apply and achieve your ‘look’ in about 45 minutes. The 100% solids epoxy has 35-45 minute working time, and then it starts to cure and you won’t be able to ‘work’ it after it starts hardening. Mixing up smaller batches of the epoxy and hardener and getting it out of the bucket and onto the floor will give you more time. We don’t recommend to mix more than 1.5 gallons (1 gallon of part A with ? gallon of part B at a time). The mix ratio is 2 PARTS OF PART

A with 1 part of part B. You can mix as much or as little at a time as you want to, as long as you hold this 2:1 ratio, and mix A and B together very well.

5. Mix your A and B together at the 2:1 ratio. Pour it on the floor in a ribbon left to right. Have your flat squeegee ready to go to spread it out evenly over the primer. Once applied to the primer, swirl it around over the primer. You can use a variety of methods to achieve decorative results including spraying, squeegeeing, etc. The epoxy will also change as it ‘self level’s. Spraying on denatured alcohol from a hand pump sprayer can make the epoxy ‘dance and swirl’, do this after you spread epoxy out. If you are using a second metallic color add small

amounts of it at this time and swirl into the first color to get the results you want. Get as much of your mixed epoxy on the floor as fast as possible as the floor is cooler and this will slow down the curing process and give you more time to work.Keep mixed epoxy cool and in the shade, out of sun and heat.

6. Once you have achieved the look you want, let the metallic epoxy cure overnight.

7. Apply clear protective topcoat. Please note that use of any non skid additive will de-gloss the floor so you may not want to use it, but this can make the floor very slippery if wet or

greasy. If using a white or clear non skid additive in a clear topcoat the non skid may show up in the clear over a dark colored base so you may want to consider using dark Aluminum Oxide as a non skid as an alternate.